One of the most important components for plastic compounding processors is a reliable, continuous and high-precision loss-in-weight feeding system. Many plastic compounding processors are still facing the problem that the product quality is not consistent, due to the fact that the loss-in-weight feeding is not reliable and repeatable.

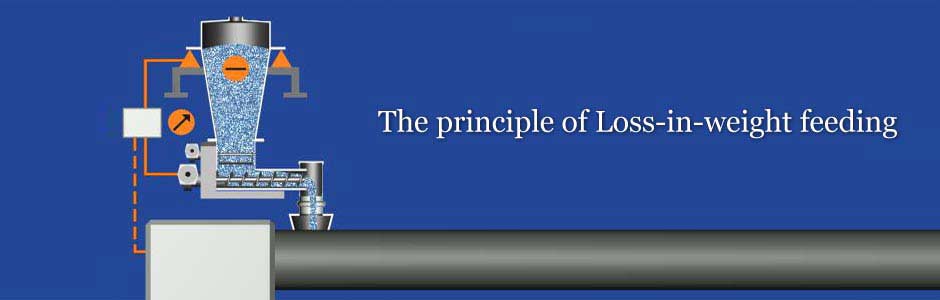

Our AZO dosing units (AZOGRAV®, AZODOS®, DOSITAINER®) in connection with our AZO®CONT is the right solution. Powder materials are discharged from the hopper by means of an agitator and fed into the dosing screws. The automatically controlled dosing screws discharge the material and the quantity discharged is precisely recorded. Through a reference variable specified by the extruder, the throughput rate is adapted to the screw speed of the loss-in-weight feeder. One of the advantages is the precise online control and quick correction in the event of deviations from expected value. When the filling level in the hopper reaches the minimum value, refilling is automatically requested. During the brief refill phase, the gravimetric dosing system continues to operate controlled by the screw speed (volumetric) and returns to gravimetric dosing as soon as the refill process has finished.

The AZO control system offers a functional scope that is tailored to the task and can be easily adapted to each respective application by means of parameters. By using functions that have been tried and tested across many applications, AZO has created a practice-oriented and perfected system with user-focused documentation. This new generation of controllers makes complex and individual programming a thing of the past.