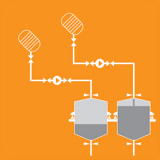

AZO provides automatic delivery systems for loading stirrer containers, mixers, conches and kneading units with sugar, corn starch, sorbitol, cocoa, maltodextrin, milk powder, full milk powder, nuts etc., including process-related and display systems.

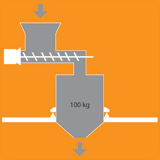

AZO utilizes external and / internal silos, loading station for bags, BIG BAGs, and drums, suction weighing systems, container systems, AZO COMPONENTER® DOSINENTER® and ManDos for additives and paints, tanks, fluid scales, process-related IT.

AZO systems for the confectionary industry reliably automate all raw materials, whether large, small or liquid components. At the same time, AZO systems are designed for safe operations , for non-clumping handling of sugar, dextrose and powder sugar and further AZO systems facilitate productions schedules with a high variety of products with frequent recipe changeovers while ensuring reliable batch traceability acc. To EU 178. Easy cleaning is as a matter of course considered as well as contamination of all forms. Finally, AZO systems in the confectionary industry help reducing your manufacturing costs and are in reliable compliance with ATEX guidelines.

Find other interesting information about AZO® Vital by following links;