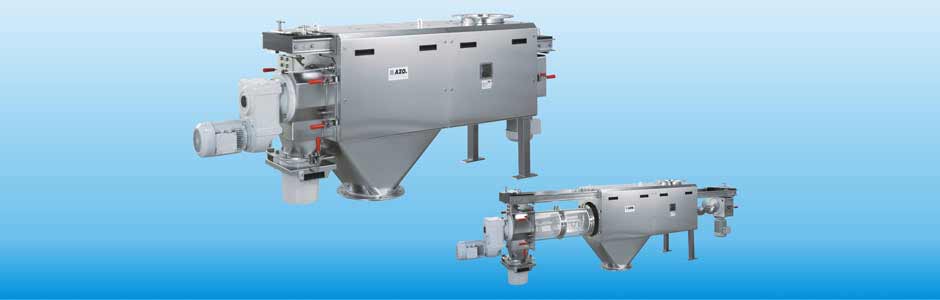

The DA type cyclone screener delivers value while being used for safety screening and fractionating of material, for eliminating foreign matter, breaking lumps, and for lifting/loosening product. The special feature of this screener type is its self-dosing function, eliminating the use of an upstream dosing device.

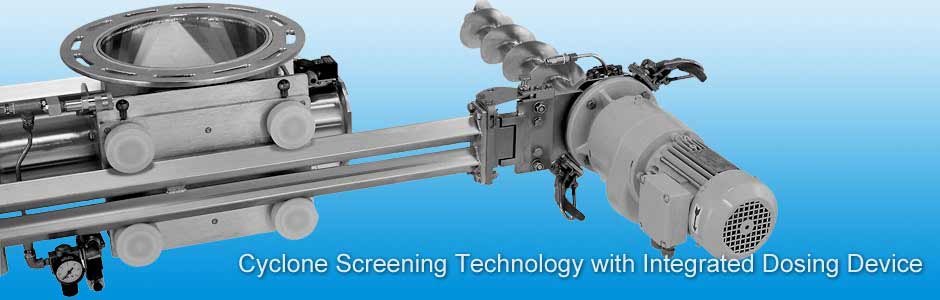

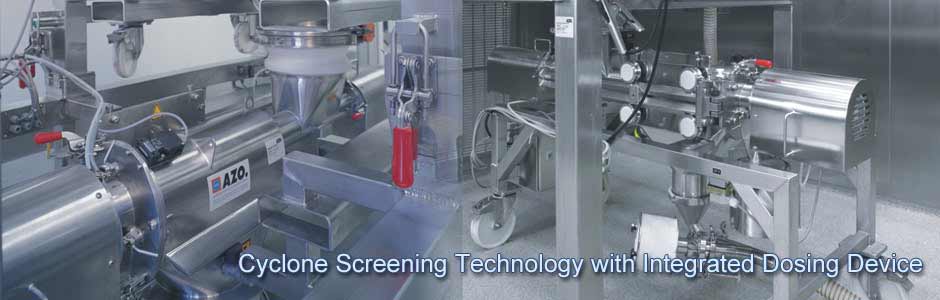

The general function principle of a rotary screener with integrated dosing device is as following: Via the product inlet, the bulk material enters the dosing screw and is transported into the screen casing. Dosing the bulk material as necessary for screening can be done by setting the screw speed by frequency converter to the value specific to the product in question. The bulk material is then taken over by the separately driven intake distributor with fluidizing bars, and gently whirled through the screen basket. The fine material drops through the screen into the outlet for fine product, the coarse material is transported to the outlet for coarse product , and there gently removed. The special extraction device with snap locks allows simply extracting and swiveling the screen basket to the side for inspection. This makes for thorough inspection and quick exchange if necessary. The dosing screw is also quickly extracted by opening its snap locks. Safety-relevant connections are governed by electric protective devices (safety switches) which switch the machine off the moment such a connection is opened. The screening mesh is held by rings, can freely vibrate, and thus cleans itself. The built-in baffle prevents too much fine product getting into the coarse-product outlet.

In short, the DA type cyclone screener does not need an extra dosing device, as a result this type of cyclone screener requires less height when integrated into a system. This reduces building costs. Further, the DA type cyclone screener is equipped with and "easy to clean extraction device" to simplify maintenance and to shorten down times.