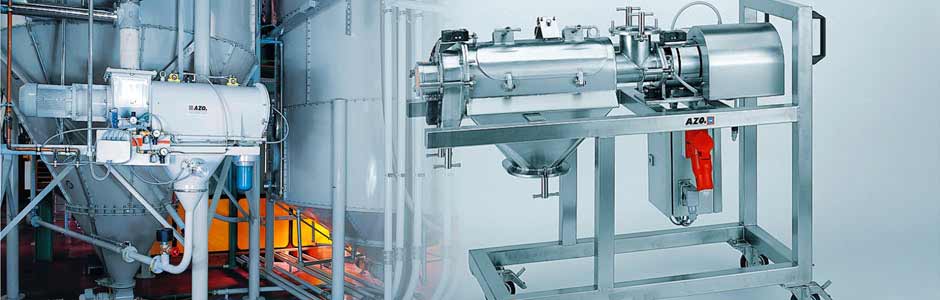

For 50 years AZO cyclone screener have been used with great success for screening and sifting powdery bulk materials in the food, plastics, pharmaceutical and chemical industry. AZO cyclone screeners are used for control screening, lump breaking, separation of agglomerates, recycling of fines, fractioning and to ensure a contamination free production. Finally, using an AZO screeners contributes to an improving constant quality output of your end product.

The general function principle of a rotary screener is as following: The product is metered into the AZO cyclone screener via the inlet pipe. This can be done by means of a rotary feeder or a metering screw. By this, the risk of bridge building above the screener can be reduced. The feeding screw transfers the product into the screening chamber where it is gently swirled through the screen fabric by the fluidizing bars. The fine good product drop through while coarse particles such as contamination and agglomerates are carried on and discharged continuously for later disposal. The baffle at the end of the screen prevents fines from entering the coarse product. The screen fabric, which is mounted on rings, can vibrate freely and therefore cleans itself automatically. It can also block blows softly and thus is largely insensitive to foreign matter. Sack fibers are eliminated too without forming a beard in the screen which might adversely adversely affect the screening.

Due to the carbon fabric of the screen, electrostatic charging, which occurs when screening e.g. PVC powder, is excluded. The screen can be exchanged easily and in a short time without using any tools. In addition, the rotor is very simple to remove. When the machine is not working, a large inspection door at the screener body makes it possible to check the complete surface of the screen basket easily by turning it 360°.

In short, AZO screeners allow a high throughput while not compromising on safe production. This helps optimizing your production costs. Further, maintenance intervals are short, therefore down times reduced to a minimum.