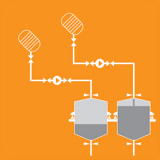

AZO provides automatic material handling systems for feeding silos and from there mixers and extruders with special grades of flour, sugar, bran, grain, ingredients and liquid components, including process leading and visualization technology.

AZO typically offers external and internal silos, filling stations for bags and big bags, suction weighing systems, fluid scales for ingredients and for minor components, AZO offers the AZO COMPONENTER®, DOSINENTER® and ManDos, all integrated and optimized by process-IT.

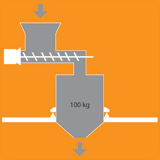

With AZO systems the highest level of reliability of your process becomes possible by automating large, medium-sized and small components from mixer loading through to the pre-mix stage. In the production of cereals and jams the handling of liquid components plays an important role, AZO reliably integrates the liquid components such as honey and syrup into the overall process. Handling of sugar may be a challenge while AZO is using all its experience to optimally handle sugar and to avoid lump formation in the first place to ensure a constant high quality output and to avoid production downtimes. Cookers are lump-free loaded by using the double-infeed principle to further increase production quality.

Find other interesting information about AZO® Food by following links;