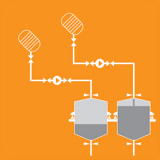

AZO provides automatic material handling systems for feeding silos and from there cleaning systems, mills and mixers with salt, starch, spices and ingredients, then to convey these completed spice mixtures to the packaging lines, including process leading and visualization technology.

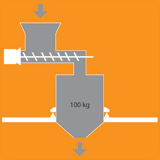

AZO typically offers external and internal silos, containers, tanks, loading stations for bags, big bags, and drums, suction weighing systems, tanks, fluid scales for ingredients and for minor components, AZO offers the AZO COMPONENTER®, DOSINENTER® and ManDos, all integrated and optimized by process-IT.

AZO systems facilitate a contamination-free recipe composition by means of a special container system. A large number and variety of recipes can be efficiently handled, through tightly toleranced production operations, a consistent quality output is achieved. The reduction of waste production leads to a reduction of production costs. Utilizing the first-in, first-out method, freshness of produced products is guaranteed. AZO designs are in compliance with HACCP and suitable for food stuffs as well as ATEX and EHDG. As a matter of course, traceability of raw materials and batches is ensured. Through a high level of automation of large, medium size and small components, AZO systems for the production of spices and flavours help you achieve highest production throughputs while providing you with a maximum flexibility at the same time.

Find other interesting information about AZO® Food by following links;