AZO provides automatic delivery systems for loading mixers with ceoliths, soda, percarbonate and additives, including process control and display technology.

Typical AZO systems in the field of producing cleaning and protective agents are external and internal silos, loading station for bags, BIG BAGs, and containers, suction weighing systems, container systems, AZO COMPONENTER®, DOSINENTER®, ManDos, drums, tanks, fluid scales, optimized by process-related IT.

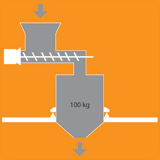

AZO systems enable high throughputs while being flexible at the same time, this leads to a cost reduction of your production process. Due to the characteristics of absorbers, AZO is using protective (low-impact) delivery and sealed systems. AZO systems reliably automate small components while being in compliance with specifications such as ATEX.

Find other interesting information about AZO® Chem by following links;