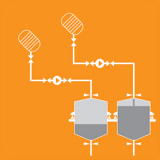

AZO provides automatic material handling systems for loading mixers with chalk, silica, additives etc., including process leading and visualization technology.

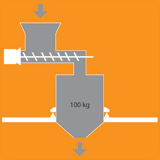

Typically used for these applications are external and internal silos, loading station for bags, BIG BAGs, and containers, AZO COMPONENTER® DOSINENTER® and ManDos suction weighing systems for additives and tiny quantities, drums, tanks, fluid scales, process-related IT.

AZO System for hygiene und cosmetic products are designed to achieve high throughputs with an high level of automation. By means of an optimal coordination of process and mixing technology through the use of tried and tested process-related IT , AZO systems facilitate an improvement of your production capacities while ensuring batch traceability and the verification of compesition. The optimal product quality is achieved through tight tolerance limits that finally lead to a reduction of production costs by avoiding waste. A key in the production of hygiene and cosmetics is the avoidance of cross-contamination. AZO Systems ensure a contamination-free batch preparation, even for small components. As a matter of course, AZO systems are design in accordance with specifications such as ATEX etc..

Find other interesting information about AZO® Chem by following links;