AZO offers automatic delivery systems for loading dissolvers, mixers, and container-mixers with epoxy resins, titanium dioxide, hardeners, bonding agents, pigments, polyesters, porcelain clay, talcum, polyurethanes, UV stabilizers, including process control and visualization technology.

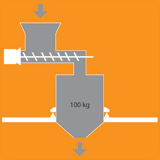

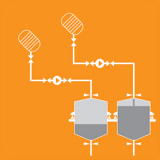

Typical AZO systems are external and internal silos, loading station for bags, BIG BAGs, and drums, suction weighing systems, container systems, AZO COMPONENTER® DOSINENTER® and ManDos for additives and paints, tanks, fluid scales, optimized with process-related IT.

AZO systems for the production of paints, lacquers and powder coatings are designed for a safe handling of a larger number of components, fluids and paints while ensuring a contamination-free batch composition. Reliable loading of container mixers during powder production as well as a production of environment-friendly products is AZO’s specialty. AZO systems are designed to facilitate a very flexible production low cleaning requirements and simple product changeovers. As a matter of course AZO systems ensure a verifiable and reproducible production at all times while being in compliance with specifications, e.g. ATEX.

Find other interesting information about AZO® Chem by following links;