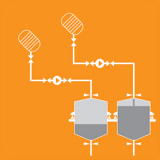

AZO systems for the production of additives and master batches include automatic delivery systems for loading mixers with plastic additives, fillers and color pigments for the manufacture of additive compounds.

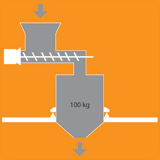

Typically used in the area of additives and master batch production are external and internal silos, filling stations for bags and BIG BAGs, container systems, AZO COMPONENTER®, ManDos, optimized by process-related IT.

AZO systems for the production of additives and master batches allow contamination-free, fully-automated recipe creation and mixer loading while at the same time enhancing efficient handling of a large number of recipes and components, the result are low investment and life-cycle costs. AZO systems can be supported via a reliable teleservice to reduce down times. As a matter of course AZO systems for the production of additives and master batches are in compliance with ATEX specifications. The control systems support a seamless documentation of each batch.

Find other interesting information about AZO® Poly by following links;