AZO provides for PVC Dryblend and PVC Extrusion processes automatic delivery systems for loading heating/cooling mixers with PVC, titanium dioxide, fillers, stabilizers, additives, modifiers, plasticizers and colour pigments including loading systems for extrusion systems with process control and display technology.

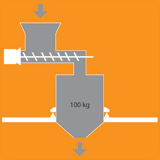

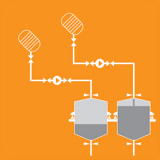

AZO systems for the production of PVC Dryblend and PVC Extrusion processes comprise of external and internal silos, loading station for bags, BIG BAGs, drums and crates, AZO COMPONENTER® DOSINENTER® und ManDos as well as suction weighing systems for additives and tiny quantities, tanks, fluid scales, optimized by process-related IT.

AZO systems with fully-automatic and reliable loading of heater and cooler mixers ensure high throughput levels of PVC Dryblend systems, the result is a cost reduction achieved through a high level of automation. A gentle extruder loading prevents mixtures from decomposing, a big plus for PVC extrusion processes as waste is reduced and product quality improved. AZO systems improve human workplaces by focusing on dust reduction, while being in compliance with ATEX specifications. The control systems used enables a reliable batch monitoring with a precise verification of composition.

Find other interesting information about AZO® Poly by following links;