AZO provides automatic delivery systems for loading compounding processes such as heater cooler mixers with plastics, fillers, fibres, additives and fluids, including process control and display technology.

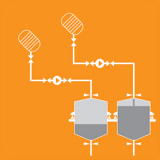

Typically used in for compounding and surface improvement applications are silos, filling stations for bags and BIG BAGS, pneumatic loading systems, continuous gravimetric metering systems, pneumatic conveying systems for transporting finished goods to the loading stations, all optimized by process-related IT.

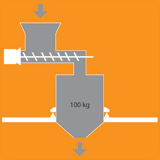

Wear-resistant pneumatic conveying systems for compounds from AZO preserve your products while continuous gravimetric metering and handling of granulate, powder, fluids, glass fibres and rods are used to feed extruders to enable higher production outputs. AZO systems allow rapid product changeovers with easy-to-clean systems while ensuring reliable reproducibility and batch tracking. Simple sample extraction and metal separation processes are no challenge for AZO pneumatic conveying systems for compounds and surface improvements.

Find other interesting information about AZO® Poly by following links;