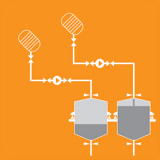

AZO provides automatic delivery systems for loading mixers and dissolvers with PVC, chalk, plasticizers, foaming agents and additives, including process control and display technology systems as required by PVC coating systems.

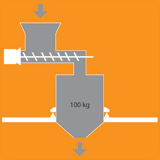

Typically AZO provides external and internal silos, filling stations for bags and BIG BAGs, screening systems, suction weighing systems, ManDos, fluid weighing systems, optimized by process-related IT.

AZO systems for the production of PVC coatings simplify high-volume handling of silo goods. Secure loading of the paste mixer is ensured by full automation. Finally, the high level of automation leads to a cost reduction in production and therefore improves the efficiency of your plant. AZO systems improve human workplaces by focusing on dust reduction, handling and weighing of fluid components is done in a safe way. The control system ensures reproducibility of any batch, the product quality is well documented.

Find other interesting information about AZO® Poly by following links;